Funded projects - Developing circular business models for Reece Group

The project identified three key circular economy initiatives: enhancing product repairability, optimising unwanted stock management, and developing a customer support app. These initiatives aim to reduce waste, extend product lifespans, and accelerate the shift towards more circular business models across Victoria.

Background

Reece Group is a leading supplier of plumbing, waterworks, and HVAC-R products in Australia. In FY24 Reece completed its second materiality review to understand where it should focus sustainability efforts. One of its foundational focus areas is reducing waste.

Supported by the Victorian Government’s Circular Economy Innovation Fund as part of the Circular Economy Business Innovation Centre (CEBIC), Reece wished to identify circular economy opportunities across its operations. Given the company’s extensive product range and operational scale, the challenge was to isolate the most impactful circular economy initiatives that could be effectively scaled across its business.

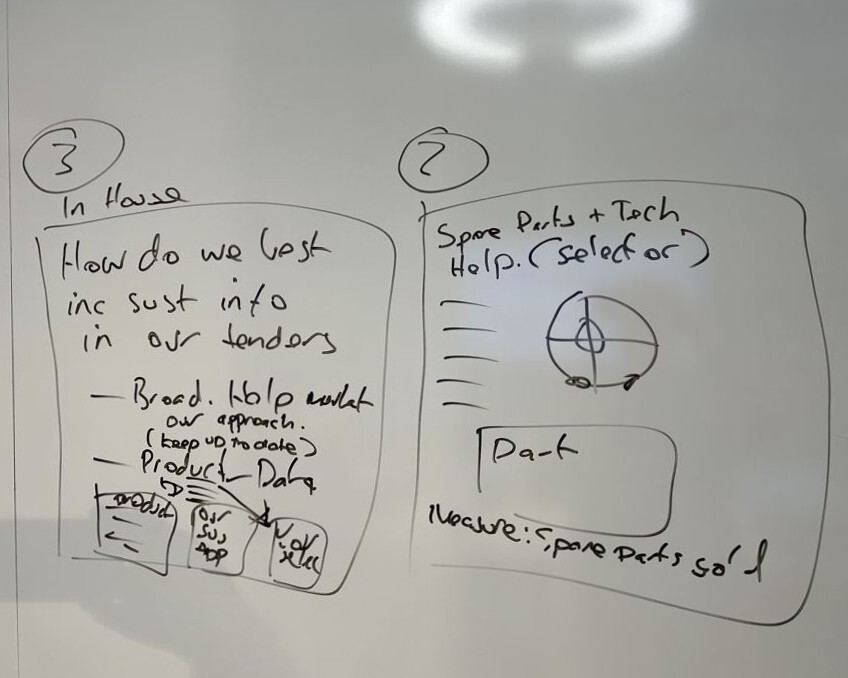

Working in partnership with Aurecon, a global engineering and consulting firm, Reece undertook a comprehensive analysis of its business to identify opportunities for circular transformation. Through extensive stakeholder engagement and detailed analysis, three key initiatives were developed to determine feasibility for implementation: enhancing product repairability, unwanted stock optimisation, and customer support app (support as a service) to facilitate repairs over replacements.

These initiatives were selected for their potential to create significant environmental impact while delivering tangible business benefits. The product repairability programme aims to extend product lifespans while the unwanted stock optimisation initiative targets substantial waste reduction. The customer support app represents an innovative approach to enabling circular practices through digital transformation.

The combination of government funding and expert partnership with Aurecon has enabled Reece to foster collaboration, maximising the project's potential impact across the building supply chain.

Stages

| 01/12/2023 | Project initiation: Conducted workshops with Aurecon to identify circular economy initiatives and develop opportunity list. |

| 16/04/2024 | Analysis phase: Completed PESTLE analysis and stakeholder workshops to evaluate opportunities. |

| 12/06/2024 | Stakeholder engagement: Conducted interviews and workshops, identified 39 opportunities, established working groups. |

| 28/06/2024 | Implementation Plan: Selected top three opportunities. Created business cases and worked with stakeholder working groups to determine feasibility. |

| 06/12/2024 | Evaluation: Initiatives currently on hold, pending budget approvals and resources required for implementation. |

Outcomes - what worked?

Reece delivered circular economy training to 50 individuals across its network, fostering increased awareness and understanding of circular economy principles.

To ensure ongoing commitment to circular economy initiatives, the business structured its Continuous Improvement team across three full-time positions: a Continuous Improvement Programme Lead, Coordinator, and Analytics Specialist.

The top three initiatives - enhancing product repairability, unwanted stock optimisation, and customer support app (support as a service) – if implemented, are projected to deliver substantial environmental benefits. These include potential annual waste reduction of approximately 6,814 tonnes and an emissions reduction of up to 11,000 tonnes* CO2-e annually.

Further and rigorous financial modelling is required to determine the initiatives’ economic viability and subsequent environmental impact. However, by reducing excess inventory costs, transportation costs and emissions and improving operational efficiency, the business expects a positive return on its investment.

*Emissions calculations are based on open source data and are not specific to Reece products, therefore more work is required to get an accurate understanding of emissions reduction potential.

Challenges

Staffing Continuity

Mid-project staff movement created challenges for maintaining momentum and knowledge retention. The team responded by implementing robust onboarding processes and cross-training existing staff, though this resulted in some project delays.

Supply Chain Complexity

Reece has an extensive and complex supply chain which is in the early stages of transformation. Any proposed changes will need to be incorporated into the transformation project and subject to that project’s timeline.

Change Management

Implementing new circular economy practices requires cultural and operational changes.

This is an ongoing process. Reece started by introducing the concept of circular economy in lunchtime education sessions.

Insights to share with other businesses

For organisations embarking on circular economy initiatives, Reece's experience highlights several key insights. First, clear vision and stakeholder engagement from the outset are crucial for success. Early involvement of employees, suppliers, and customers helps ensure buy-in.

Strong partnerships, both with expert consultants and government bodies, provide valuable support and expertise. These relationships enable pre-competitive collaboration and innovation that individual organisations might struggle to achieve alone.

Investment in education and training is essential for building internal capability and maintaining momentum. Regular monitoring and transparent communication of progress help maintain engagement and support continuous improvement.

What's next?

With business cases now in place for three initiatives, Reece is ready to allocate funding through its annual budgeting process and is keen to bring at least one of these initiatives to life in the next financial year.