Funded project – Designing Modular Construction Systems for Circular Economy - A framework for disassembly and reuse

The development of a prototype modular building using salvaged steel components from obsolete relocatable classrooms. The project demonstrated practical building circularity whilst creating frameworks for structural verification and sustainable material selection.

Background

In the traditional linear economy, buildings reaching their end-of-life are typically renovated or demolished, generating substantial waste that predominantly ends up in landfill. This wasteful approach squanders not only raw materials but also the embedded energy and labour invested in manufacturing and construction processes.

Decades of manufacturing and deploying relocatable classrooms have created an ongoing stream of outdated modular building components. Each refurbishment cycle, triggered by functional changes, pedagogical developments, and general facility wear and tear, generates significant waste. While sustainably manufactured products are important, they represent only part of the solution. The critical challenge of maintaining materials at their highest value for longer periods remained largely unaddressed.

Rendine Constructions, the University of Melbourne, and prefabAUS formed a unique partnership to tackle this challenge. Each partner brought specific expertise: Rendine's advanced modular construction technology, the University's internationally recognized academic rigour, and prefabAUS's extensive industry network. Together, they developed an innovative approach to transform redundant structural steel modules into valuable housing solutions, addressing both sustainability goals and construction capacity constraints.

Stages

| 16/10/2023 | Project Planning & Development: Initiated project, mobilised team, detailed scope development, established roles and budget control framework. |

| 15/11/2023 | Project Research: Conducted salvage operations, documented modules, performed structural analysis and validation, researched suitable technologies. |

| 15/03/2024 | Detailed Design: Selected final products, controlled budget, resolved design details, documented specifications, identified material sources. |

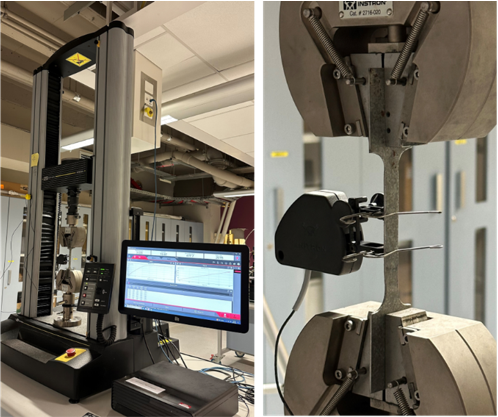

| 05/08/2024 | Implementation & Construction: Procured materials, completed structural repairs, installed cladding and services, conducted testing and reporting. |

Outcomes – what worked?

The project successfully delivered a prototype that demonstrated practical building circularity. Key achievements included extending the lifecycle of 40-year-old structural steel elements by an additional 40-50 years, creating ten full-time equivalent positions across various trades, and achieving significant environmental benefits.

The initiative resulted in substantial waste reduction, saving approximately 1.9 tonnes of materials per prototype. When scaled to 20 houses, this represents a potential saving of 37 tonnes of waste materials. The project also achieved a greenhouse gas emissions reduction of 2.9 tonnes through the reuse of existing steel frames.

The team successfully developed regulatory frameworks for verifying recycled steel components' structural integrity and created a sustainable materials database using the Material Circularity Indicator framework. The prototype incorporated innovative sustainable materials, including reconstituted waste timber cladding, compressed straw panels, and recycled packaging board.

Challenges

Product & Materials Selection

The team faced challenges in distinguishing between marketing claims and documented sustainability credentials. Many circularity measurement tools proved more relevant to international contexts than Australian conditions, and local recycling infrastructure limitations affected end-of-life solutions.

Circular Products, Availability & Price-point

Procurement of specialist circular construction products presented challenges regarding local availability, lead times, and costs. Some challenges were mitigated through supplier partnerships and material donations.

Industry Resistance to Change

Traditional construction approaches rarely consider material adaptability and reuse. The team needed to advocate for circular principles across suppliers, regulators, designers, and trades, though stakeholders became supportive once they understood the benefits.

Insights to share with other businesses

Success in circular economy projects requires clear goals, extensive research, and a long-term strategic perspective. Organizations should expect longer timelines and higher initial costs compared to conventional projects. Strong partnerships are crucial, as innovative solutions often emerge from diverse expertise collaboration.

Projects must navigate regulatory challenges, as current building standards primarily accommodate traditional materials and methods. Alignment with long-term organizational goals is essential for creating a foundation for future development.

What's next?

Building on the project's success, Rendine and stakeholders are exploring several opportunities to expand their circular construction economy work. These include implementing outcomes across other relocatable school buildings, developing disaster relief solutions, and identifying additional reusable components from obsolete buildings.

While the reuse of steel superstructures proves more cost-effective than new construction, sustainable products often carry a "green premium." Future growth depends on government and client incentives, continued research through the University of Melbourne capstone project, and leveraging the successful partnership between Rendine, prefabAUS, and University of Melbourne.

From the grantee

"Rendine Constructions and its collaborating partners University of Melbourne and prefabAUS are invested in furthering sustainability and circularity in their respective areas. This is motivated by a shared belief that the 'business as usual' approach to construction can only deepen existing problems, at a time when the environment is increasingly threatened by carbon emissions and associated challenges."