Funded project – Decreasing waste from apple juice and cider manufacturing

A collaborative project to convert apple pomace waste into high-value cellulose and co-products using an innovative biorefinery approach. The process successfully extracted five valuable products from juice manufacturing waste, demonstrating both environmental and economic benefits whilst advancing circular economy principles.

Background

Nearly half of Australia's apple production occurs in Victoria, with approximately 30% used for juicing. This generates substantial pomace waste, accounting for around 20% of apples' dry biomass. Traditionally sent to landfill, this waste contributes to greenhouse gas emissions, particularly methane, while representing a missed economic opportunity.

The project aimed to address this waste management and environmental challenge by developing technology to convert apple pomace into high-value cellulose and co-products using a biorefinery approach. This solution not only diverts organic waste from landfills but also creates sustainable raw materials for textile production, promoting circular economy principles.

A cross-sector collaboration brought together expertise from Bellevue Orchard (raw material - pomace), Deakin University (bioprocessing), HeiQ (textile applications), JET Technology (pilot-scale processing), Austeng (engineering), and Consulting & Implementation Services (project management). This consortium leveraged complementary skills and infrastructure to deliver a sustainable, impactful solution across the supply chain.

Stages

| 31/05/2024 | Compositional analysis and lab-scale biorefinery process development achieving 90% cellulose purity with co-products. |

| 26/07/2024 | Detailed product analysis, specifications development, and technology transfer documentation for scale-up. |

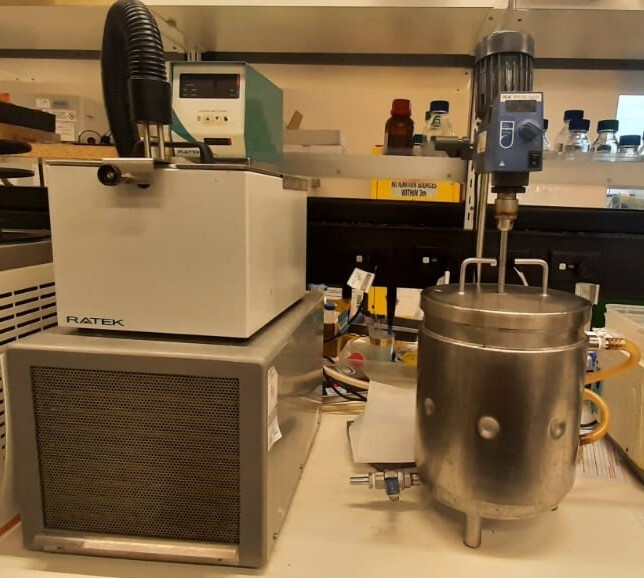

| 30/09/2024 | Pilot-scale production of cellulose and co-products from apple pomace. |

| 31/10/2024 | Testing cellulose in textile applications, including production of short fibres for additive applications. |

| 29/11/2024 | Preliminary manufacturing facility design for cellulose and co-product production. |

Outcomes – what worked?

The project successfully developed and validated a scalable biorefinery process to extract five high-value products from apple pomace: cellulose, phenolics, pectin, hemicellulose, and simple sugars. The process demonstrated successful transition from laboratory to pilot-scale production while maintaining high yields and consistent quality.

Environmental benefits included the potential to divert 1,100 tonnes of apple pomace from landfill annually, avoiding 1,857 tonnes of CO2 emissions. The project created 1.2 FTE positions during development, with potential for 50 new jobs across facility construction and operations.

Through innovative biorefinery technologies and cross-industry collaboration, the project demonstrated how waste can become commercially viable products, driving resource efficiency while supporting circular economy principles.

Challenges

Low Protein Content

Upon research, low content (4.1% dry weight) of protein, made its extraction economically unviable, requiring a shift from six to five target products.

Product Quality

Thermal and mechanical processing during juice production and thermo-chemical treatments affected the quality of cellulose and phenolics, which can be addressed through proper preservation and process optimisation.

Scaling from Lab to Pilot

Viscosity challenges during scale-up reduced pectin yields, resolved through adjustments to stirring speeds and water addition.

Process Cost Efficiency

High solvent use and energy costs were addressed through implementation of recovery systems and energy-efficient adjustments.

Coordination Across Partners

Complex interdependencies and lead time for test results occasionally delayed milestone delivery within the condensed timeframe.

Insights to share with other businesses

- Begin with a comprehensive waste stream analysis to identify viable products and processes.

- Focus on high-value end-use products with proven market applications.

- Engage collaborative partners with diverse expertise.

- Conduct early lab and pilot scale trials.

- Establish clear governance and project management structures.

- Build strong communication and stakeholder engagement.

What’s next?

The validated biorefinery process is ready for commercial scale-up, with potential to divert 1,100 tonnes of apple pomace annually while creating 50 new jobs. Future investment will support process optimisation, capacity expansion, and market development across textiles, food, cosmetics, and bioplastics industries.

The project framework can be extended to other fruit, vegetable, and agricultural processing industries, demonstrating how circular economy solutions drive both economic growth and sustainability.

From the grantee

"As a long-standing orchard and a fruit processor we pride ourselves in making use of every part of the produce that comes from our orchard and orchards around us. The CEBIC funding has allowed us to explore ways of finding more valuable uses for our waste that will reduce our reliance on imported product or products derived from less sustainable means, ensuring that we continue to be success into the future."

More information

Research News - Can organic waste from industry be turned into new products? A new Deakin REACH partnership will explore what's possible.